Description:

SHH - FS High Speed 4&6 Corner Folder Gluer: With independent synchronized motors for stable running. Specially designed extra wide and strong upper & lower belts for corrugated boxes.

|

Name |

SHH-FS High Speed 4&6 Corner Folder Gluer |

|

Model |

SHH-1050/1250/1450/1650/1850/2050FS EXPORT |

|

Cardboard |

200-800 g/m² |

|

Corrugated board |

A/B/C/E/F-Flute Optional EB/AB-Flute |

|

Max. Belt Speed |

Max. 280 m/min |

|

Jogging Speed |

20 m/min |

|

Max. Air Requirement |

0.7 m³/min |

|

Feeding way |

Automatically and continuously feeding |

|

Way of folding |

Fold 1 and fold 3 are 180°and 135°, Fold 2 and fold 4 are 180°, Bottom folded and glued 4&6 corner |

|

Glue Material |

Water-base cold glue |

|

Total Power Requirement |

22KW 380V 50HZ 3P (1050/1250/1450) 26KW 380V 50HZ 3P (1650/1850/2050) |

|

Weight |

6.5/7/7.5Ton (1050/1250/1450) 8.2/8.7/9.2Ton (1650/1850/2050) |

|

Over dimension |

16.5x1.8(2/2.2)x 1.7m (1050/1250/1450) 18.5x 2.4(2.6/2.8)x 1.9m (1650/1850/2050) |

|

SHH-FS EXPORT Series folder gluer machine, - Independent Synchronized motors throughout entire machine for stable running - Extra wide and strong upper and lower belts specially designed for corrugated boxes - Motorized carrier system for easy operation - Upper carrier electrical-driving system and pneumatic pressing system applied for corrugated board - Special fish tail features designed for corrugated box common problems (We can customize for other sizes.) |

|

Feature introduction

|

|

Feeding

Adjustable feeding belts to ensure easy adjustment, stable and smoothly feeding.

Continuously Variable Speeder to ensure feeding internal and stable transmission.

One-touch Pneumatic knife, easy for the adjustment of feeding belts. |

|

Alignment

Alignment section, which automatically corrects the box after it is ejected from the paper feed section. |

|

|

|

pre-folding & Back Folder

Pre-fold and back folder section: Equipped with right/ left pre-fold to complete 180° pre-folding on small side. Equipped with right/left to complete 135°pre-folding, according to the size of the box, thus making it easier to spread cartons |

|

|

Bottom-lock& Back Folder

Bottom Gluer section: All gluing drums can be loaded and unloaded;

Two upper gluing drums (right and left) and two lower gluing drums (right and left), to be selected depending on actual needs; Glue quantity in gluing drums is adjustable, thus ensuring stability and easy maintenance; Gluing roller is 4mm thick in standard version and can be customized according to customer requirements;

Made with aluminum, gluing drum is firm and durable;

Bottom gluing is completed by 4 groups of crash-locking mechanism. |

|

Folding

Lengthened folding to avoid the unevenness while the rapid forming of cartons and make it come to perfection. |

|

|

|

Full pressing

Creaser section: Adopts continuous and automatic box collecting mechanism to ensure boxes enter the Conveyer section neat and well aligned; Equipped with electronic counter/automatic mark spraying kick plate for counting and mark-spraying purposes;

Equipped with air compressor system and creasing channel system;

Pressure rollers can be adjusted depending on box types and paper quality to achieve flawless box creasing. |

|

|

Transmission

Equipped with feeding paper inspection device.

Equipped with impacting device to press the paper after accounting and make it easy to pack paper. |

|

4&6-corner section

4&6-corner section: Rear-crash lock of mechanical operation in coordination with paper delivery photoelectric, thus ensuring every box continuously and accurately crashlocked and speedily, stably to make 4&6 angle box. |

|

|

|

Auto motor adjust

The machine adapt electrical plate adjustment,fast to adjust |

|

CCTV monitors

The machine adapt CCTV monitors could see machine product |

|

|

|

touchscreen

The machine adapt touchscreen adjustment, fast to adjust |

|

Spraying System (water-base cold)

For irregular box, Need Extra Spraying System.

Equipped with three guns, convenient in the production various special box, gluing quickly and accurately sizing.

(Options: customized on user order) |

|

|

Machine Optional configuration list |

|

|

Optional hot melt system

The tank less hot melt system is designed for melting and pumping of thermoplastic hot melt in granulate form. It gently melts on demand and therefore is applicable for both high and low glue consumption applications. Optional volume control monitors changes in adhesive consumption. Thanks to the fast heat-up time of 16 minutes to 160 °C the Concept Stream is quickly operational. In addition, the adhesive +system achieves a high melting rate performance of 8 kg/h or 15 kg/h with minimum space. |

|

|

|

Optional Plasma system

Through surface coating treatment,to strengthen the adherence and make cartons easier to be glued. |

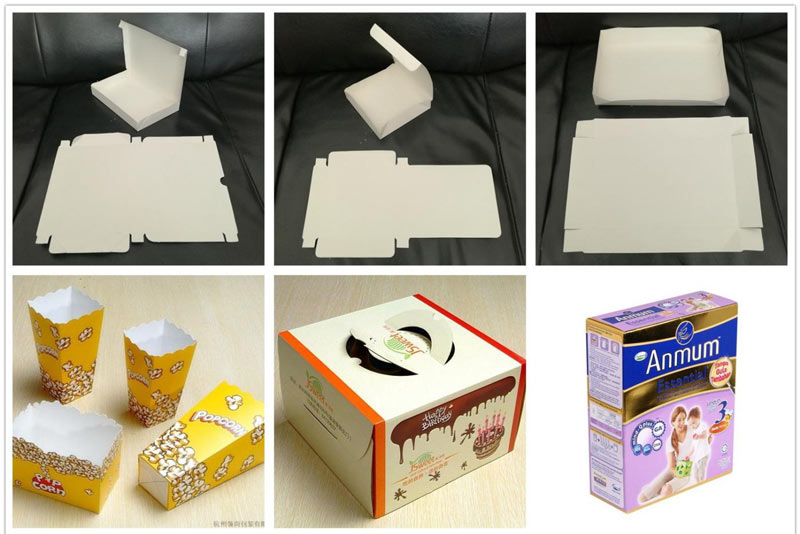

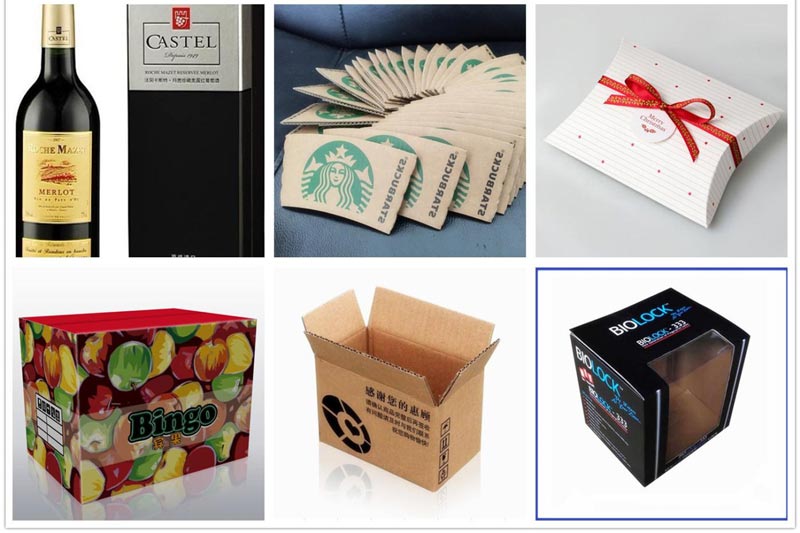

Samples

|

Four corner box type and size:(mm) |

|

||||||

|

Model |

1050FS |

1250FS |

1450FS |

1650FS |

1850FS |

2050FS |

|

|

A+B+C |

180-1000 |

180-1200 |

180-1400 |

180-1600 |

180-1800 |

180-2000 |

|

|

B Min |

130 | 130 | 130 | 130 | 130 | 130 | |

|

F |

70-800 |

70-800 |

70-800 |

70-800 |

70-800 |

70-800 |

|

|

G Max |

800 |

800 |

800 |

800 |

800 |

800 |

|

|

H Min |

10 |

10 |

10 |

10 |

10 |

10 |

|

|

L |

25-100 |

25-100 |

25-100 |

25-100 |

25-170 |

25-170 |

|

|

Six corner box type and size :(mm) |

|

||||||

|

Model |

1050FS |

1250FS |

1450FS |

1650FS |

1850FS |

2050FS |

|

|

A+B+C+D+E |

290-1000 |

290-1200 |

290-1400 |

340-1600 |

340-1800 |

340-2000 |

|

|

B+C Min |

80 |

80 |

80 |

140 |

140 |

140 |

|

|

B Min |

80 |

80 |

80 |

80 |

80 |

80 |

|

|

C Min |

30 |

30 |

30 |

30 |

30 |

30 |

|

|

D Min |

70 |

70 |

70 |

70 |

70 |

70 |

|

|

F |

70-800 |

70-800 |

70-800 |

70-800 |

70-800 |

70-800 |

|

|

G Max |

800 |

800 |

800 |

800 |

800 |

800 |

|

|

H Min |

10 |

10 |

10 |

10 |

10 |

10 |

|

|

L |

25-100 |

25-100 |

25-100 |

25-100 |

25-170 |

25-170 |

|

|

Flat box type and size :(mm) |

|

||||||

|

Model |

1050FS |

1250FS |

1450FS |

1650FS |

1850FS |

2050FS |

|

|

A+B+C+D |

200-1000 |

200-1200 |

200-1400 |

200-1600 |

280-1800 |

280-2000 |

|

|

C+D Min |

100 |

100 |

100 |

100 |

140 |

140 |

|

|

D Min |

25 |

25 |

25 |

25 |

25 |

25 |

|

|

F Min |

100 |

100 |

100 |

100 |

100 |

100 |

|

|

G |

150-800 |

150-800 |

150-800 |

150-800 |

150-800 |

150-800 |

|

|

Lock bottom carton type and size:(mm) |

|

||||||

|

Model |

1050FS |

1250FS |

1450FS |

1650FS |

1850FS |

2050FS |

|

|

A+B+C+D |

250-1050 |

250-1150 |

250-1350 |

250-1550 |

380-1750 |

380-1950 |

|

|

C+D Min |

125 |

125 |

125 |

125 |

190 |

190 |

|

|

D Min |

25 |

25 |

25 |

25 |

25 |

25 |

|

|

F Min |

100 |

100 |

100 |

100 |

100 |

100 |

|

|

G |

150-800 |

150-800 |

150-800 |

150-800 |

150-800 |

150-800 |

|

|

H Min |

30 |

30 |

30 |

30 |

30 |

30 |

|

NOTE:The machine speed should be based on the actual sample box size .

Workshop

Carton boxes are an essential part of packaging and shipping, widely used in industries ranging from e-commerce to food deliv...

Currently! Pizza boxes are usually recyclable. However, many pizza boxes are soaked with cheese and grease, which affects the...

The corrugated box folder gluer machine plays a vital role in the packaging industry. It can precisely fold and glue flat cor...

Folder Gluer Machine is an important equipment for folding and gluing cartons in the carton, packaging and printing industrie...