How to reduce the waste rate of the folder gluer in the paper glue process

With the development of social automation, most companies use automated box-gluer equipment for box-gluing, which can effectively reduce labor costs, control serious labor, and make production more useful! As an indispensable transmission accessory in the automatic folder-gluer equipment, the feeder belt of the folder-gluer machine is of great importance! However, in the application process, there is an important problem that cannot be ignored: that is, the waste rate of the traditional manual paste box process is very low. Although the automatic folder gluer equipment has many advantages, its waste rate has always been a headache for users.

So how to reduce the box-gluer waste rate when using the box-gluer equipment?

1. Start with the adhesive of the product. According to the different work body and structure produced by each packaging box, use the adhesive reasonably, which can adapt to the production line. After the box is glued, it can penetrate quickly and produce initial adhesion. force. In order to make the bonding effect between the adhesive and the substrate better, a half-piercing line can be made in the life position to enhance the bonding fastness. In addition, the selection of adhesives should be targeted, and different types of adhesives should be selected for different types of jobs (such as film coating, water-based varnish, UV printing, etc.).

2. Control the import direction of materials. In order to complete the carton gluing process better and faster, the fiber direction of the cardboard box or the corrugated direction of the corrugated carton should be as close as possible to the direction of the feeder belt of the gluer Straight. If the corrugated direction of the corrugated box is parallel to the direction of the box, the folding line of the corrugated box can generally be made into a double line.

3. Treatment of carton planning details: detailed planning of the orientation of the carton gluing machine; the paper feeding edge of the carton should be planned as a straight line; the large carton products should be planned with the die-cut oblique method; products should be avoided during the production process. Conflict with internal components.

Company Profile

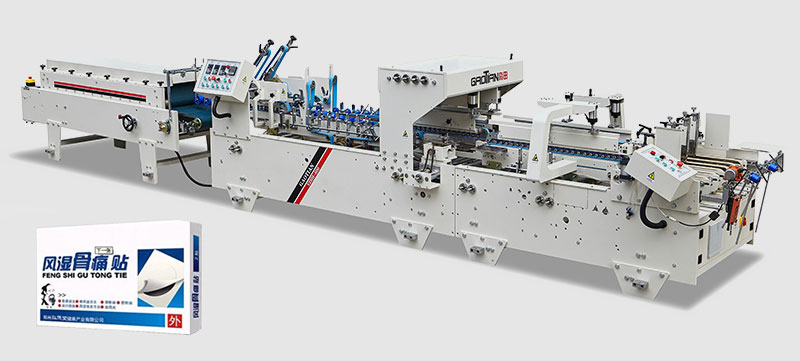

Wenzhou Gaotian Packing Machine Co., Ltd. mainly researches, develops, produces and sells folding and gluing machines and carton laminating machines. It also provides on-site installation, commissioning and training services to make customers satisfied after sale. It always puts technical standards and product quality in the first place, takes the responsibility of meeting the requirements of printing and packaging production enterprises, and strives to produce post-press equipment with customer-satisfied. Our company has a professional product R&D team, advanced production management system, high-precision converting center, and experienced and skilled assembly staff.