What are the Precautions for Using the Automatic Corrugated Box Folder Gluer Machine?

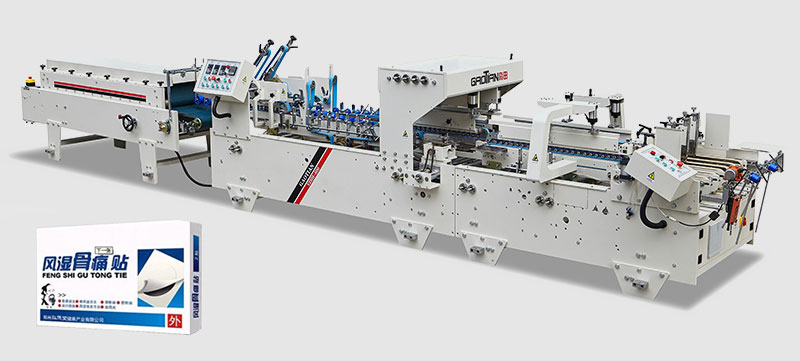

The automatic corrugated box folder gluer machine plays a vital role in the packaging industry. It can precisely fold and glue flat corrugated cardboard into three-dimensional cartons. Using rollers, folding plates, and other mechanisms for folding and a gluing system for bonding, it can manufacture various types of cartons, including single-walled and double-layered ones. These cartons are widely used in e-commerce, food and beverage, and industrial packaging sectors. However, to ensure the normal operation of the machine, production efficiency, and product quality, the following aspects need to be noted when using the automatic corrugated box folder gluer machine:

I. Installation and Commissioning

Installation Environment Requirements

1.Select a suitable installation site. The ground should be flat and firm to bear the weight of the machine and avoid vibration or displacement of the machine during operation. At the same time, the installation site should be dry and well-ventilated, away from water sources and corrosive substances to prevent rusting of the machine and damage to electrical components due to moisture.

2.Ensure sufficient installation space so that operators can easily perform operation, maintenance, and repair work. A certain passage should be reserved around the machine to facilitate the handling of raw materials and the output of finished cartons.

Installation Steps and Commissioning Key Points

1.Strictly follow the installation instructions provided by the manufacturer. During the installation process, pay attention to the installation sequence and connection methods of each component to ensure firm and reliable connections. For example, the belts and chains of the transmission parts should be installed correctly with appropriate tension. If the tension is too loose, it may cause slipping and affect power transmission; if it is too tight, it will increase component wear and reduce the service life.

2.After the installation is completed, conduct a comprehensive commissioning. The commissioning includes checking whether the wiring of the electrical system is correct and whether the power supply voltage meets the requirements; checking whether the movement of mechanical parts is smooth and whether lubricating oil needs to be added to joints, bearings, and other parts; commissioning the folding and gluing systems to ensure accurate folding angles and even glue application. Some sample cardboard can be run for a trial to observe the forming effect of the cartons and make fine adjustments to the machine until the ideal production state is achieved.

II. Operation Specifications

Preparations Before Starting the Machine

1.Before starting the machine, conduct a comprehensive inspection of the machine. The inspection contents include: checking whether there are any sundries or tools left on the machine and cleaning the work area; checking the glue supply system to ensure that there is sufficient glue and no precipitation or blockage. The viscosity of the glue should meet the production requirements, and it should be adjusted or replaced if necessary; checking the cardboard conveying system to ensure that the conveyor belt is undamaged and the rollers rotate flexibly; checking the folding and gluing parts, such as whether the folding plates are intact and in the correct position, and whether the surface of the gluing roller is clean.

At the same time, adjust the various parameters of the machine according to the production order requirements. This includes the size specifications of the cartons, such as length, width, and height. Adjust the positions of the corresponding baffles, push plates, and other components; set the folding and gluing speeds, which should be reasonably selected according to factors such as the material and thickness of the cardboard and the drying speed of the glue to avoid poor carton forming or un-dried glue due to excessive speed, and to also avoid affecting production efficiency due to too slow speed.

Monitoring During Operation

1.During the operation of the machine, the operator should closely monitor the operation status of the machine. Pay attention to observing the conveying of the cardboard to ensure that the cardboard can enter the machine smoothly without jamming. If the cardboard is not conveyed smoothly, the machine should be stopped immediately for inspection. The possible reasons may include oversized cardboard, foreign objects on the conveyor belt, or uneven tension of the conveyor belt.

2.Monitor the folding and gluing process. Check whether the folding angles are accurate. If any folding deviation is found, the angle or position of the folding plate should be adjusted in a timely manner. Observe the glue application situation to ensure that the glue is evenly applied on the cardboard and the amount of glue is appropriate. Too much glue may cause glue overflow and affect the appearance of the carton, while too little glue may result in poor adhesion. At the same time, pay attention to the drying situation of the glue. If the drying time of the glue is too long, it may be necessary to adjust parameters such as the temperature and ventilation of the machine to speed up the drying of the glue.

3.Regularly check the quality of the finished cartons. Randomly sample a certain number of finished products for inspection to see whether the size of the cartons meets the requirements, whether the folding is neat and firm, and whether the glued parts are tight and without glue opening. If any quality problems are found, the cause should be analyzed in a timely manner and the machine should be adjusted or repaired accordingly.

Shutdown Operation

When the production task is completed, perform the shutdown operation. First, stop feeding the cardboard into the machine. After all the remaining cardboard in the machine has been processed, turn off the main motor power. Then, turn off the glue supply system and clean the residual glue on the gluing roller, glue tank, and other parts to prevent the glue from drying and affecting the next use.

Clean the machine, removing dust, paper scraps, and other debris from the machine surface, conveyor belt, folding plates, and other parts. Inspect each moving part. If any wear or abnormal conditions are found, they should be recorded and arranged for repair or replacement in a timely manner. Finally, restore the machine parameters to the initial settings to prepare for the next startup.

III. Maintenance and Care

Daily Maintenance

1.Cleaning the machine after each day's work is an important part of daily maintenance. Use a clean rag to wipe the machine surface and remove impurities such as dust and oil to keep the machine appearance clean. For hard-to-clean areas, such as corners and gaps, small cleaning tools can be used for cleaning.

2.Check the lubrication status of each lubrication point, such as bearings, chains, and guide rails, and add an appropriate amount of lubricating oil in a timely manner to ensure smooth movement of the parts and reduce wear. At the same time, check whether the bolts and nuts at each connection point are loose. If loose, they should be tightened in a timely manner to prevent component loosening and machine failure.

3.Check whether the wiring of the electrical system has any looseness, damage, or other conditions to ensure reliable electrical connections. Observe the working status of electrical components, such as motors and sensors, to see if there is any abnormal heating, noise, or other phenomena. If any problems are found, the machine should be stopped immediately for inspection and repair.

Regular Maintenance

1.Regularly replace wearing parts, such as conveyor belts, rubber rollers, and blades. These parts will wear out after long-term use and affect the performance and product quality of the machine. Develop a reasonable replacement plan according to the service life and actual wear of the parts to ensure that the machine is always in good working condition.

2.Maintain the transmission system of the machine, including cleaning the belts and chains, checking and adjusting their tension, and inspecting the pulleys and sprockets to ensure that they are free of wear and deformation. Regularly change the oil in the gearbox and clean the inside of the gearbox to ensure the smoothness and reliability of gear transmission.

3.Inspect and maintain the folding and gluing systems. Regularly clean the paper scraps and glue residues on the folding plates and check whether the flatness and angles of the folding plates have changed. If necessary, adjust or replace them in a timely manner. Conduct a deep cleaning of the gluing system, including the glue tank, gluing roller, and glue pipe, to ensure even glue application and no blockage. At the same time, check the working status of the glue pump to ensure that it can normally deliver the glue.

4.Conduct a comprehensive inspection and commissioning of the machine every quarter or half a year, including checking the accuracy of the machine, such as the size accuracy of the cartons and the folding angle accuracy, and adjusting the parts that do not meet the requirements. Check the performance of each control system, such as the temperature control system and the speed control system, to ensure that they are accurate and reliable. Through regular maintenance, the service life of the machine can be extended, and the production efficiency and product quality can be improved.

IV. Safety Precautions

Personal Safety Protection for Operators

1.Operators must wear personal protective equipment, such as work clothes, safety helmets, protective gloves, and safety shoes, when operating the automatic corrugated box folder gluer machine to prevent accidental injuries during the operation. For example, when cleaning the machine or handling jamming and other faults, operators may come into contact with moving parts or sharp edges, and protective gloves can play a role in protecting hands.

2.It is strictly prohibited to perform cleaning, maintenance, or adjustment operations when the machine is running. If such operations are required, the machine must be stopped first, and it must be ensured that the machine is in a completely stopped state, the power supply must be cut off, and warning signs such as "Do Not Switch On" must be hung to prevent others from accidentally starting the machine.

Safety Protection Devices of the Machine

1.Ensure that the safety protection devices on the machine are intact and working properly. For example, the emergency stop button should be tested regularly to ensure that the machine can be stopped quickly in an emergency. The safety protection door should be closed tightly. When the protection door is opened, the machine should stop running immediately to prevent operators from touching dangerous parts.

2.Set effective protection devices for dangerous areas such as the transmission parts and heating parts of the machine, such as protective covers and guardrails, to prevent operators from accidentally touching. At the same time, set obvious safety warning signs around the machine to remind non-operators to stay away from the machine and avoid accidents.

3.Correct use and maintenance of the Automatic corrugated box folder gluer machine are crucial for improving production efficiency, ensuring product quality, and ensuring personnel safety. Only by strictly following the above precautions can the machine operate stably for a long time and create greater value for the enterprise.