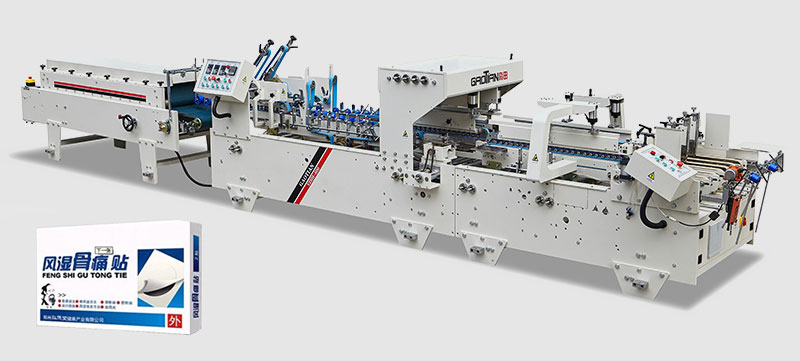

Working Principle and Process of Corrugated Box Folder Gluer Machine

In the packaging industry, the corrugated box folder gluer machine is a key device for transforming corrugated cardboard into finished cartons. The efficiency and accuracy of its working principle and process directly affect the production quality and efficiency of cartons.

Paper Feeding System

Paper feeding is the first step in carton gluing. Corrugated box folder gluer machines usually adopt the bottom - feeding method and use sponge belts to convey paper blanks. To ensure that the paper blanks can be accurately separated and enter the subsequent processes, the machine is equipped with an elastic and adjustable paper - feeding knife. Combined with a vibration motor, the paper blanks remain stable and are separated one by one during the conveying process. At the same time, the paper - feeding drive system is controlled by a photoelectric - controlled clutch. When an abnormal position of the paper blank is detected, the clutch will automatically adjust to ensure that the paper blank can accurately enter the gluing section, avoiding problems such as paper jams and ensuring the continuity of the entire production process.

Gluing System

After the paper blank enters the gluing section, the gluing system starts to work. Most corrugated box folder gluer machines are equipped with an advanced hot - melt glue system, which is controlled by photoelectric sensors and can be precisely adjusted according to the size of the paper blank and the required gluing position. During the gluing process, the glue wheel evenly applies an appropriate amount of glue to the specific parts of the paper blank. The thickness and width of the glue application can be adjusted through the parameter settings of the machine. For example, for some cartons that require stronger adhesion, the amount of glue applied can be appropriately increased; while for some small - sized cartons or those with high - appearance requirements, the gluing range can be precisely controlled to avoid glue overflow affecting the appearance of the cartons.

Folding and Molding

The glued paper blank enters the folding and molding area, which is the core working part of the folder gluer machine. In this area, the paper blank will go through a series of folding mechanisms and be precisely folded according to the design requirements of the carton. Generally, preliminary pre - folding is carried out first, bending the edges of the paper blank at a predetermined angle to prepare for subsequent precise folding. Then, through the internal and external molds of the molding section, under the coordinated control of photoelectric sensors and air cylinders, the paper blank is accurately folded and pressed into shape. For example, for common flap - type cartons, the machine will first fold the two - side flaps of the carton, and then fold and bond the upper and lower flaps, finally forming a complete carton shape. During the entire folding and molding process, the accuracy and stability of the machine are crucial, which directly determine the dimensional accuracy and appearance quality of the cartons.

Output and Sorting

The folded and molded cartons are conveyed to the output device. The output device usually includes a conveyor belt and a sorting mechanism. The conveyor belt smoothly sends the formed cartons out of the machine, and the sorting mechanism arranges the cartons neatly for subsequent packaging and handling. During the output process, a final quality inspection of the cartons is also carried out, such as checking whether the bonding of the cartons is firm and whether the dimensions meet the requirements. If unqualified cartons are found, they will be automatically removed to ensure that the cartons entering the next link are all products with qualified quality.