Can you recycle pizza boxes?

Currently! Pizza boxes are usually recyclable. However, many pizza boxes are soaked with cheese and grease, which affects their recycling value, because grease interferes with fiber separation during paper recycling and reduces the quality of recycled paper.

What are the uses of recycled pizza boxes?

It starts with the material of the pizza box. Pizza boxes are usually made of corrugated cardboard, which contains one or more layers of corrugated core paper and two sides of flat paper (noodle paper). This structure gives it good strength and cushioning properties to protect the pizza. Recycled pizza boxes can have the following uses:

· Corrugated cardboard recycling: Recycled pizza boxes can be made into new corrugated cardboard after a series of treatments, such as removing grease and separating fibers. New corrugated cardboard can be used to produce various packaging boxes, including daily necessities packaging boxes, express packaging boxes, etc. This is both environmentally friendly and cost-effective.

· Pulp reuse: Pizza boxes can also be processed into pulp. Pulp can be used to make paper, which can be used to print newspapers, magazines, books, etc. It can also make some paper products, such as paper fillers, paper partitions, etc. For example, in some e-commerce packaging, fillers made of recycled pulp can be used to protect goods from damage during transportation.

· Insulation materials: In the construction field, recycled pizza box fibers can be processed into insulation materials. These materials can be used for insulation of walls, roofs and other parts of buildings.

· Energy recovery: If the fiber cannot be recycled due to severe pollution, it can be sent to a biomass power plant as fuel for combustion and power generation, but this is less recycled than other products.

How are pizza boxes produced?

Pizza box production can be divided into the following three steps:

1. Cardboard production:

Prepare raw paper materials such as kraft paper and place them on the unwinding rack. The corrugated core paper is processed into a wavy shape by a corrugator, and then the corrugated core paper and the noodle paper are glued with glue using a bonding device to make corrugated cardboard. In this step, corrugators and bonding equipment are key, ensuring the basic structure and strength of the cardboard and preparing for subsequent processing.

2. Printing and cutting:

Use printing equipment such as flexographic printing machines to print the brand, pattern, text and other information of the pizza shop on the corrugated cardboard, so that the pizza box has a promotional and logo function. Then use a cutting machine to cut the printed cardboard according to the predetermined size. If there are special shape requirements, a die-cutting machine is also required to obtain a precise shape and press out creases for subsequent molding.

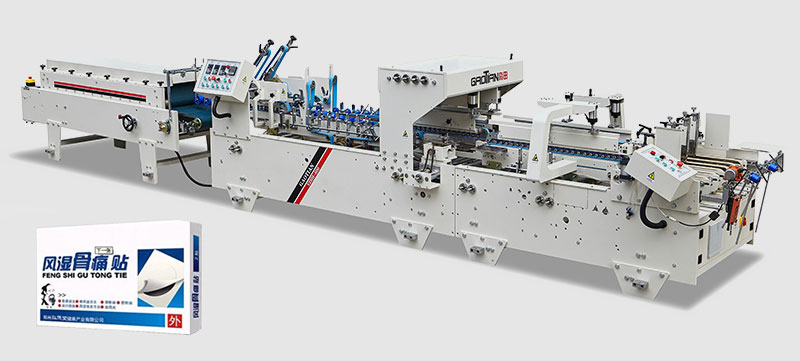

3. Folding and molding:

The cut cardboard is fed into the automatic folder gluer machine. The machine first folds the cardboard along the crease, and then applies glue to the part that needs to be glued to complete the box molding process, and finally produces a complete pizza box.