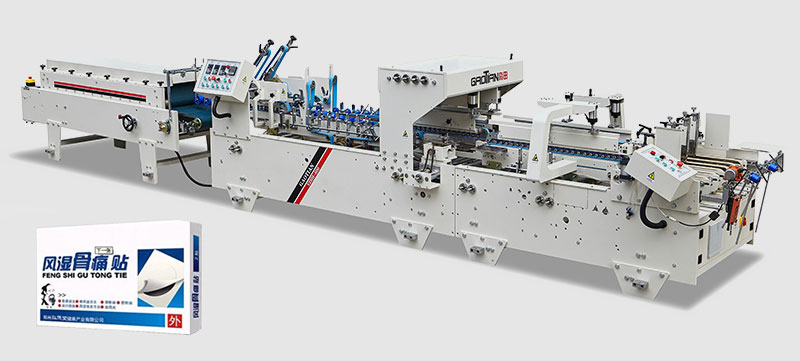

Automatic 4 - 6 Corner Folder Gluer Machine: A Revolutionary Force in the Packaging Industry

In the field of packaging manufacturing, technological advancements are constantly driving the improvement of production efficiency and product quality. As an advanced piece of equipment, the Automatic 4 - 6 Corner Folder Gluer Machine is reshaping the packaging production landscape with its unique performance.

I. Exceptional Functional Features

Flexible Multi - corner Forming:The most remarkable function of this equipment is its ability to simultaneously form four - to six - corner paper boxes. The precise mechanical structure and intelligent control system within it work in tandem, enabling quick and accurate switching between different corner - type modes. Whether it's a regular four - corner paper box for daily commodity packaging or a distinctive six - corner paper box to meet the packaging needs of high - end gifts or specialty products, it can handle them with ease, greatly enriching the diversity of packaging designs.

Precise Folding and Gluing:The Automatic 4 - 6 Corner Folder Gluer Machine is equipped with a high - precision folding device that precisely folds the cardboard into the desired shape according to preset size and angle parameters. Meanwhile, its advanced gluing system is truly remarkable. It can automatically and accurately regulate the amount of glue based on the cardboard's material, thickness, and the specific specifications of the paper box. This ensures that the glue is evenly applied in the appropriate positions, avoiding both the appearance - spoiling glue overflow caused by excessive glue and the poor adhesion resulting from insufficient glue, providing a firm and aesthetically pleasing bonding effect for the paper box.

II. Prominent Technical Advantages

Highly Automated Operation:Automation is one of the core advantages of this equipment. Operators only need to place the cardboard in a specific loading area, and the equipment can automatically and continuously complete a series of subsequent processes, including feeding, folding, gluing, bonding, and finished - product output. This feature not only significantly reduces the tediousness of manual operation and labor costs but also remarkably improves the stability and consistency of the production process. It effectively avoids product quality fluctuations caused by human factors, greatly enhancing production efficiency and product qualification rates.

Efficient Production Speed:The high - speed rotating mechanical components within the equipment and the carefully optimized process flow endow it with excellent production efficiency. It can complete the forming of multiple paper boxes within a unit of time. Compared with traditional manual or semi - automatic folder gluing equipment, the output has increased several times or even dozens of times. With the booming development of the e - commerce industry, in the face of massive product packaging demands, the Automatic 4 - 6 Corner Folder Gluer Machine can respond rapidly, helping enterprises efficiently complete order tasks and gain an edge in market competition.

III. Extensive Application Scenarios

Food Packaging Field:In the food industry, the hygiene, sealing performance, and aesthetics of packaging are of utmost importance. The paper boxes produced by the Automatic 4 - 6 Corner Folder Gluer Machine, with their good sealing performance, can effectively block external dust, moisture, and microorganisms, ensuring the freshness and quality of food. Their precise forming process and delicate appearance also add appeal to the food, contributing to enhancing the market competitiveness of products. The packaging of various pastries, candies, dried goods, and other foods all rely on the efficient support of this equipment.

Gift Packaging Industry:Gift packaging emphasizes uniqueness and refinement to convey emotions and highlight value. The Automatic 4 - 6 Corner Folder Gluer Machine can produce various exquisitely shaped and exquisitely crafted paper boxes, meeting the diverse design requirements of gift packaging. Whether it's a chocolate gift box for Valentine's Day, a special Christmas gift box, or a high - end gift box for business gifting, it can create a unique packaging for the gift with its multi - corner forming advantage, enhancing the overall grade of the gift.

IV. Maintenance and Care Points

Daily Cleaning and Maintenance:To ensure the continuous and efficient operation of the equipment, daily cleaning is essential. Regularly clean the paper scraps,glue residues, and other debris remaining on the surface and inside of the equipment to prevent their accumulation from affecting the normal operation of mechanical components. Pay particular attention to cleaning the folding and gluing parts to ensure they remain clean and smooth, avoiding mechanical failures or uneven glue application caused by impurities.

Regular Component Inspection:According to the requirements of the equipment's maintenance manual, regularly inspect key components such as drive chains, belts, and rubber hoses to check for wear, aging, looseness, and other conditions. Once a problem is detected, repair or replace it in a timely manner to ensure the stable performance of the equipment. At the same time, regularly lubricate each mechanical component to reduce friction and wear, extending the service life of the equipment.