How to easily solve the problem of belt deviation of the folder gluer

Deviation and its handling. There are many reasons for the deviation of the belt conveyor. The main reason is the low installation accuracy and poor daily maintenance.

In the process of installing the conveyor, try to keep the head and tail rollers and the intermediate rollers on the same centerline, and be parallel to each other to ensure no deviation or less deviation. In addition, the strap joints should be correct, and the circumferences on both sides should be the same. If there is a deviation, check the following factors and determine the reason for adjustment. The frequently checked parts and treatment methods for deviations are:

1. Check the deviation value of the two planes of the bearing seat of the head and tail frame. If the deviation of the two planes is greater than 1mm, the two planes should be adjusted in the same plane. The adjustment method of the head roller is as follows: if it runs off the right side of the roller, the bearing seat on the right side of the roller should move forward or the bearing seat on the left side should move backward. If you run off to the left of the drum, the bearing seat on the left side of the drum should move forward or the bearing seat on the right side should move backward. The adjustment method of the tail roller is just the opposite of that of the head roller.

2. Check the position of the material on the conveyor belt. If the material is not centered on the cross section, it will cause deviation. If the material deviates to the right, the belt deviates to the left, and vice versa. The material should be centered as much as possible during use. In order to reduce or avoid this kind of deviation, a baffle plate can be added to change the direction and position of the material.

3. Check the misalignment between the horizontal centerline of the roller and the longitudinal centerline of the conveyor belt. If the non-coincidence value exceeds 3mm, the long mounting holes on both sides of the roller set should be used to adjust it. The specific method is which side is deviated, which side of the roller set moves forward in the forward direction, or the other side moves backward.

Company Profile

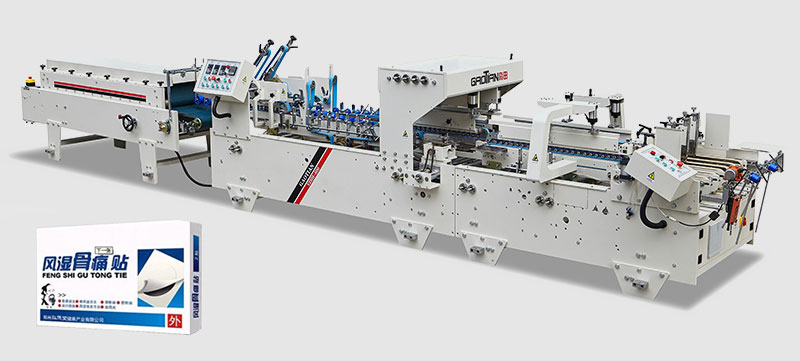

Wenzhou Gaotian Packing Machine Co., Ltd. mainly researches, develops, produces and sells folding and gluing machines and carton laminating machines. It also provides on-site installation, commissioning and training services to make customers satisfied after sale. It always puts technical standards and product quality in the first place, takes the responsibility of meeting the requirements of printing and packaging production enterprises, and strives to produce post-press equipment with customer-satisfied. Our company has a professional product R&D team, advanced production management system, high-precision converting center, and experienced and skilled assembly staff.