Problems prone to daily use of laminating machine

The assembly paper machine is now widely used in the printing industry. It can be said to be a machine and equipment that cannot be replaced by the basis of pre-printed cartons. It has a great impact on the entire process of production and processing. Even the application requirements are getting higher and higher, but not everyone can apply it correctly. Now let's take a look at the problems that are prone to occur in the daily work of the paper laminator.

First, ignore the steps. Many people think that the operation of assembling the paper machine is very easy. When the equipment is turned on, it will be opened very quickly. In fact, the facial tissues and corrugated boxes are reinstalled at the time of application. Otherwise, it is easy to learn and training content. Therefore, the relative position should be adjusted during the whole process, and the uneven cardboard should be rubbed flat.

Second, equipment adjustment errors. If you want to properly assemble the paper machine, you must adjust it correctly in your daily routine to prevent errors. For example, if there is a loosening of the transmission chain, it must be messed up immediately to avoid vertical or collision. If the upper and lower rollers are not cleaned and the glue accumulates, it will also affect the transportation.

Third, the maintenance of equipment has not been done well. If any thing is not properly maintained, there is no way to correct its quality. Therefore, after buying an automatic paper laminator, regardless of its accuracy, regardless of the current stage of work efficiency, appropriate learning and training The relevant operators should do a good job of cleaning up on time to avoid damage.

If you want to make carton printing production and processing easier, you must take a good look at such key machinery and equipment. These contents cannot be ignored.

Company Profile

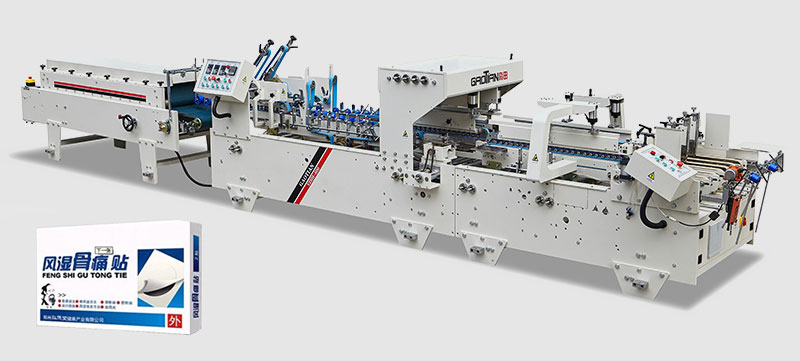

Wenzhou Gaotian Packing Machine Co., Ltd. mainly researches, develops, produces and sells folding and gluing machines and carton laminating machines. It also provides on-site installation, commissioning and training services to make customers satisfied after sale. It always puts technical standards and product quality in the first place, takes the responsibility of meeting the requirements of printing and packaging production enterprises, and strives to produce post-press equipment with customer-satisfied. Our company has a professional product R&D team, advanced production management system, high-precision converting center, and experienced and skilled assembly staff.